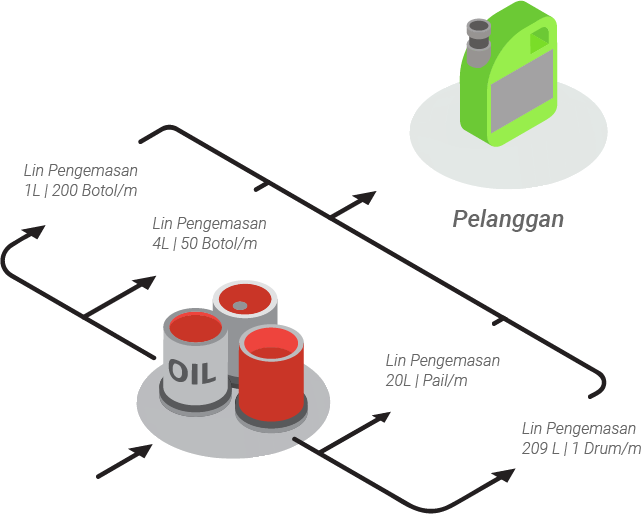

WGI's Blending Plant was specially designed by Mid America Engineering, Inc. from Chicago, United States and has a production capacity of 120,000 MT lubricants per year.

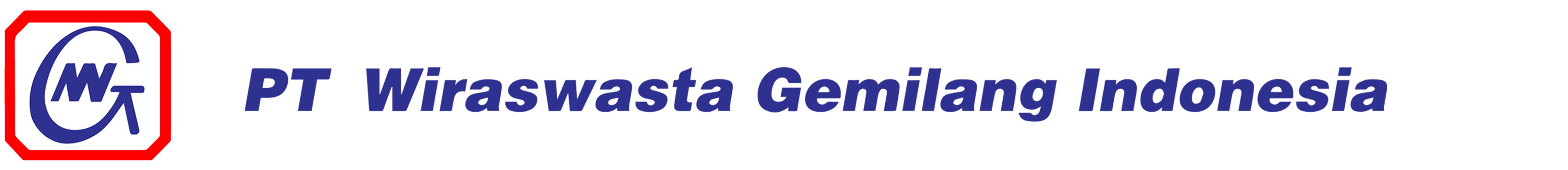

The modern blending toll facility has a process of mixing high-grade base oil and additives with special formulations; and the all-computerize Automatic Batch Blending System (ABB).

With this advanced technology and facilities, the results of WGI lubricants quality based on any variety of requests and specification will always be highly maintained and guaranteed.

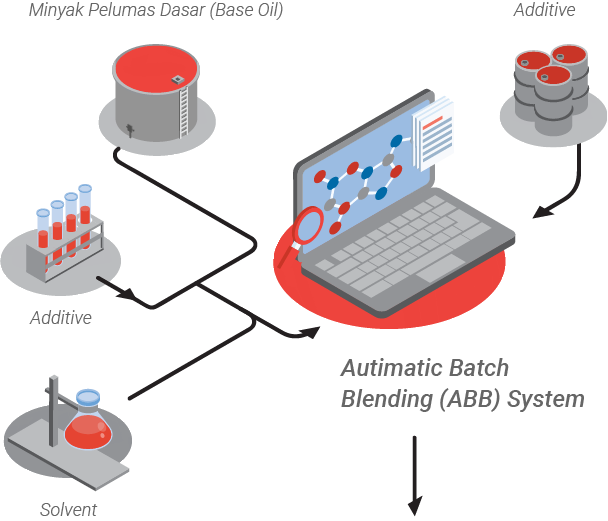

One by one the base oil is pumped into the blender to be measured / weighed in the blender according to the recipe / formula. In the blender all the raw materials are graded, stirred until homogeneous and sometimes also heated to accelerate their homogeneity to become lubricants.

Guaranteed quality and quality products are demands. The QC team is responsible for all product quality, raw materials, and packaging.

Storage of products is not as complicated as storing raw materials. Lubricant products are sufficiently stored at ambient conditions in storage tanks.